Understanding Leaf Springs

The Unsung Heroes of Your Suspension

Leaf springs are a cornerstone of vehicle suspension systems that silently working to deliver a stable and comfortable ride. But, what exactly are these unsung heroes and how do they keep our vehicles performing optimally? Let's dive into the fascinating world of leaf springs !

What are Leaf Springs?

At its core, a leaf spring is a flexible component designed to absorb and store energy then release it. Think of it as a robust shock absorber that also helps manage the weight of your vehicle.

During this cycle, the stress in the spring must not exceed a certain maximum to avoid settling or premature failure. This consideration limits the amount of energy which can be stored in the spring.

While they might be heavier in mass than some other spring types like coil springs, leaf springs offer a unique advantage and they can also serve as an attaching linkage or structural member of the suspension system.

Laminated Leaf Springs

Example of Laminated Leaf Springs

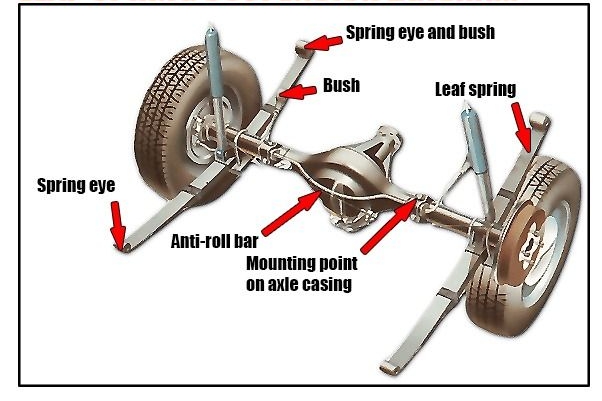

The Anatomy of a Leaf Spring Suspension System

Ever wondered what makes up a leaf spring system? In a typical light truck rear suspension, you'll find these key players:

The front eye of the spring and one end of the shackle are mounted to the frame bracket through bushing and pins. The rear eye of springs is connected to the other end of shackle through bushings and eye bolt. It's a clever setup that allows for flexibility and movement!

The Multi-Talented Leaf Spring: What Does It Do?

Leaf springs are true workhorses, performing multiple critical functions to ensure your vehicle's performance and safety:

Vehicle Weight Support

They support the vehicle weight and maintain chassis ride heights.

Suspension System Linkage

They can be used as an attaching linkage or structural member of the suspension system.

Tire Alignment

Leaf springs help keep the tires aligned on the road.

Smoother Ride

They provide for a smoother ride by absorbing bumps and dips in the road.

Vehicle Alignment & Control

Leaf springs maintain the vehicle's alignment, which includes:

- Controls the rear end Wrap-up.

- Controls the rate at which the Chassis Rolls.

- Controls Axle Damping.

- Controls Brake Damping forces.

- Controls Lateral Forces such as side load.

The characteristics of leaf springs are affected primarily by the spring rate, the change of load per unit of deflection and the deflection of the spring.

Types of Leaf Springs

Beyond the traditional leaf spring, suspension technology offers a few variations:

Laminated Leaf Springs (Multi leaf Springs)

Traditional multi-leaf springs consist of several layers of metal strips of different lengths stacked on top of each other. This design provides progressive spring rate and load-carrying capacity.

Parabolic Spring

Long taper or parabolic springs feature a varying thickness along their length, providing a more refined ride quality while maintaining load capacity. They typically have fewer leaves than traditional leaf springs.

Air Suspension Springs (Air Link Springs)

Air suspension springs use compressed air contained within a flexible bellows to support the vehicle's weight. They offer adjustable ride height and stiffness, providing superior comfort and handling characteristics.

Where Do You Find Leaf Springs?

Leaf springs are workhorses in the commercial vehicle sector. A commercial vehicle is defined as a type of motor vehicle used for transporting goods and passenger. They are classified as Bus, Truck (Light, Medium & Heavy), Trailer & Heavy Equipment.

Buses

Leaf springs are crucial for the stability and ride comfort of buses, supporting heavy loads while ensuring passenger comfort.

Light Trucks (below 5 tons)

Leaf springs provide robust suspension for light trucks, balancing load capacity with ride quality for everyday use.

Medium Trucks (up to 12 tons)

Medium trucks rely on leaf springs for load-bearing and stability, often using multi-leaf configurations for increased durability.

Heavy Trucks (above 12 tons)

Heavy-duty leaf springs are essential for heavy trucks, providing superior strength and durability for demanding transportation tasks.

Trailers

Trailers utilize leaf springs for effective load distribution and stability, ensuring safe transport of goods.

Heavy Equipment

Heavy equipment, such as construction machinery, benefits from the durability and load-bearing capacity of leaf springs.